GLYCEROL DEHYDROGENASE from Cellulomonas sp.

GYD-301

| Appearance: | White amorphous powder, lyophilized | ||

|---|---|---|---|

| Activity: | GradeⅢ 50U/mg-solid or more (containing approx. 50% of stabilizers) |

||

| Contaminant: | NAD oxidase ≤1.0×10⁻³% | ||

| Stabilizer: | BSA | ||

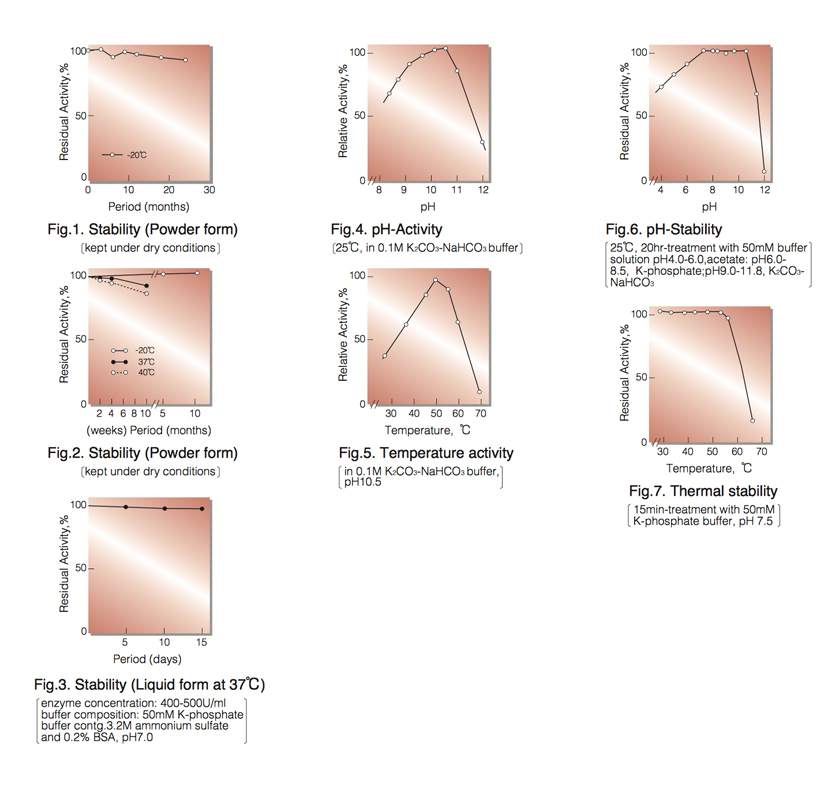

| Stability: | Stable at -20°C for at least 6 months (Fig.1) |

|---|---|

| Molecular weight: | approx. 390,000 |

| Isoelectric point : | 4.4±0.1 |

| Michaelis constants : | 1.1×10⁻²M (Glycerol), 8.9×10⁻⁵M (NAD⁺) |

| Structure : | 10 subunits (42,000) per enzyme molecule |

| Inhibitors : | p-Chloromercuribenzoate, o-phenanthroline, monoiodoacetate, heavy metal ions (Co⁺⁺, Ni⁺⁺, Cu⁺⁺, Zn⁺⁺, Cd⁺⁺) |

| Optimum pH : | 10.0-10.5(Fig.4) |

| Optimum temperature: | 50°C(Fig.5) |

| pH Stability: | pH 7.5-10.5 (25°C, 20hr)(Fig.6) |

| Thermal stability: | below 55°C (pH 7.5, 15min)(Fig.7) |

| Substrate specificity: | This enzyme has the highest specificity for glycerol and 1,2- propanediol, and also oxidizes glycerol-α-monochlorohydrin, ethylene glycol and 2,3-butanediol (Table 1). The oxidative reaction is stimulated by K⁺, NH⁺₄ and Rb⁺. |

| Effect of various chemicals: | (Table 2) |

APPLICATIONS

This enzyme is useful for enzymatic determination of glycerol and of triglyceride when coupled with lipoprotein lipase (LPL-311, LPL-314) in clinical analysis.¹ ² ⁾

ASSAY

Principle:

glycerol dehydrogenase

Glycerol+NAD⁺ ► Dihydroxyacetone+NADH+H⁺

The appearance of NADH is measured at 340nm by spectrophotometry.

Unit definition:

One unit causes the formation of one micromole of NADH per minute under the conditions described below.

Method:

| A. Carbonate-bicarbonate : buffer, pH 11.0 | 0.2M (Prepare by mixing 0.2M K₂CO₃ and 0.2M NaHCO₃ to reach pH 11.0). |

|---|---|

| B. Glycerol solution: | 0.3M |

| C. Ammonium sulfate solution: | 1.0M |

| D. NAD⁺ solution: | 10mM [Weigh 143.5mg of NAD⁺(MW=717.45) and dissolve in 18.0ml of H₂O and, after adjusting the pH to 7.0 with 0.5 N KOH, fill up to 20.0ml with H₂O] (Should be prepared fresh) |

| E. Enzyme diluent: | 20mM K-phosphate buffer pH 7.5. |

Procedure

| Concentration in assay mixture | |

|---|---|

| Carbonate buffer | 0.10 M |

| Glycerol | 0.10 M |

| NAD⁺ | 1.0mM |

| Ammonium sulfate |

33 mM |

1. Prepare the following working solution, immediately before use.

30.0 ml Carbonate-bicarbonate buffer, pH 11.0 (A)

22.0 ml Substrate solution (B)

2.0 ml Ammonium sulfate solution (C)

6.0 ml NAD⁺ solution (D)

Be sure the pH in the range (pH 10.0-10.5). If not, adjust the pH to 10.5 with 1.0 N KOH or 1.0N HCl, and store on ice in a brownish bottle.

2. Pipette 2.9ml of the working solution into a cuvette (d=1.0cm) and equilibrate at 25°C for about 5 minutes.

3. Add 0.1ml of the enzyme solution* and mix by gentle inversion.

4. Record the increase in optical density at 340nm against water for 3 to 4 minutes in a spectrophotometer thermostated at 25°C and calculate theΔOD per minute from the initial linear portion of the curve (ΔOD test).

At the same time, measure the blank rate (ΔOD blank) by using the same method as the test except that the enzyme diluent is added instead of enzyme solution.

* Dissolve the enzyme preparation in ice-cold enzyme diluent (E), dilute to 0.10-0.25U/ml with the same buffer and store on ice.

Calculation

Activity can be calculated by using the following formula :

ΔOD/min (ΔOD test−ΔOD blank ) ×Vt × df

Volume activity (U/ml) = =ΔOD/min×4.82×df

6.22×1.0×Vs

Weight activity (U/mg)=(U/ml)×1/C

- Vt

- : Total volume (3.0ml)

- Vs

- : Sample volume (0.1ml)

- 6.22

- : Millimolar extinction coefficient of NADH (㎠/micromole)

- 1.0

- : Light path length (cm)

- df

- : Dilution factor

- C

- : Enzyme concentration in dissolution (c mg/ml)

REFERENCES

- T.Nishina; Rinsho Kensa(Japanese), 22, 1304 (1978).

- M.Sugiura, et al.; Clin, Chim.Acta, 81, 125 (1977).

- R.M.Burton; Methods in Enzymology, vol.1, p.397 (S.P.Colowick & N.O.Kaplan eds.), Academic Press, New York-

London (1955).

| Substrate | Relative activity(%) | Substrate | Relative activity(%) |

|---|---|---|---|

| Glycerol | 100 | 2,3-Butanediol | 52.6 |

| Glycerol-α-monochlorohydrin | 48.5 |

Xylitol | ― |

| Ethylene glycol | 7.8 |

D-Mannitol | ― |

| 1,2-Propanediol | 132 |

D-Glucose | ― |

| 1,3-Propanediol | ― | Methanol | ― |

| 1,3-Butanediol | ― | Ethanol | ― |

| 1,4-Butanediol | ― |

―, Not detected

| Chemical | Concn.(mM) | Residual activity(%) |

Chemical | Concn.(mM) | Residual activity(%) |

|---|---|---|---|---|---|

| None | − | 100 | PCMB | 0.1 | 25 |

| Metal salt | 1.0 | MIA | 1.0 | 78 | |

| MgCl₂ | 100 |

NaN₃ | 1.0 | 110 | |

| CaCl₂ |

97 | NAF | 1.0 | 108 |

|

| SrCl₂ | 98 |

EDTA | 1.0 | 101 | |

| BaCl₂ | 95 | KCN | 1.0 | 94 | |

| MnCl₂ | 94 | o-Phenanthroline | 1.0 | 13 | |

| CoCl₂ | 57 | ||||

| NiCl₂ | 50 |

||||

| CuSO₄ | 2.4 |

||||

| ZnCl₂ | 1.5 | ||||

| CdCl₂ | 11 |

PCMB, p-Chloromercuribenzoate; MIA, Monoiodoacetate; EDTA, Ethylenediaminetetraacetate.

To get a quote, contact us at info@toyobousa.com, or INQUIRY.