GLYCEROL KINASE from Microorganism

GYK-311

| Appearance: | White amorphous powder, lyophilized | ||

|---|---|---|---|

| Activity: | GradeⅢ 30 U/mg-solid or more |

||

| Contaminants: | Catalase ≤1.0×10⁻¹% NADH oxidase ≤1.0×10⁻³% Adenosine triphosphatase ≦1.0×10⁻³% |

||

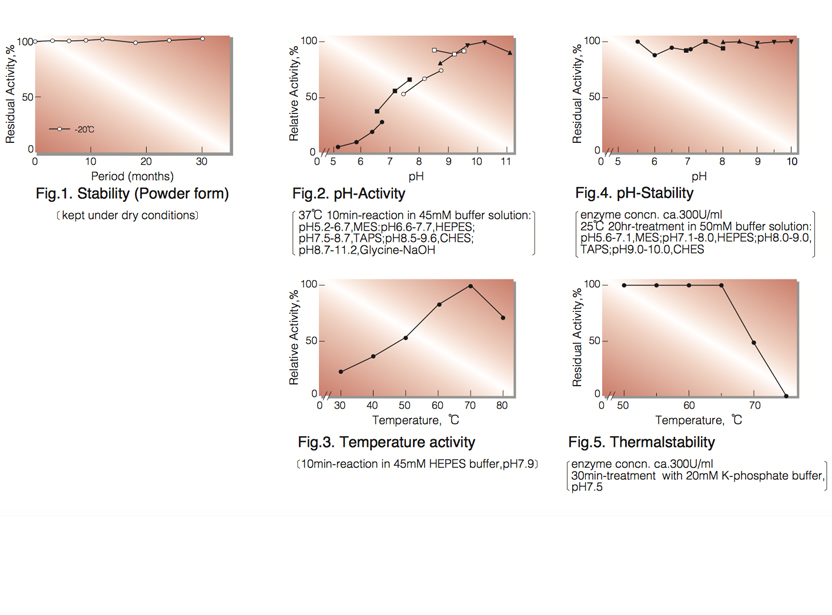

| Stability: | Stable at -20°C for at least One year (Fig.1) |

|---|---|

| Molecular weight : | approx. 220,000 (by gel filtration) |

| Structure : | Four subunits of approx. 58,000 |

| Isoelectric point: | 4.3 |

| Michaelis constants : | 9.4×10⁻⁵M (Glycerol), 1.3×10⁻⁵M (ATP), 2.1×10⁻³M (Dihydroxyacetone) |

| Inhibitors: | p-Chloromercuribenzoate, Hg⁺⁺, Ag⁺ |

| Optimum pH : | 10.0(Fig.2) |

| Optimum temperature: | 70°(Fig.3) |

| pH Stability: | pH 5.5-10.0 (25°C, 20hr)(Fig.4) |

| Thermal stability: | below 65°C (pH 7.5, 30min)(Fig.5) |

| Substrate specificity: | (Table 1) |

| Effect of various chemicals: | (Table 2) |

APPLICATIONS

This enzyme is useful for enzymatic determination of glycerol and triglyceride when coupled with glycerol-3-phosphate oxidase (=G-3-P oxidase, G3O-321) or pyruvate kinase and lactate dehydrogenase (LCD-209, LCD-211, LCD-221), lipoprotein lipase (LPL-311, LPL-314) in clinical analysis.

ASSAY

Principle:

glycerol kinase

Glycerol+ATP ► Glycerol-3-P+ADP

Mg++

G-3-POD

Glycerol-3-P+O₂ ► Dihydroxyacetone-P+H₂O₂

Peroxidase

2H₂O₂+4-Aminoantipyrine+Phenol ►Quinoneimine dye+4H₂O

The appearance of quinoneimine dye is measured at 500nm by spectrophotometry.

Unit definition:

One unit causes the formation of one micromole of hydrogen peroxide (half a micromole of quinoneimine dye) per

minute under the conditions described below.

Method:

| A. Glycerol solution: | 0.3M (Should be prepared fresh) |

|---|---|

| B. 4-AA solution: | 0.1 % (100mg of 4-aminoantipyrine / 100ml of H₂O) |

| C. Phenol solution: | 0.1 % (100mg of phenol / 100ml of H₂O) |

| D. Peroxidase solution: | 20mg Peroxidase (110 purpurogallin units/mg)/100ml of H₂O |

| E. G-3-POD solution: | 20U/ml (dissolve in 200 mM HEPES buffer, pH 7.9) |

| F. Buffer solution: | 200mM HEPES, pH 7.9 contg. 20mM MgCl₂ and 40mM ATP (should be prepared freshly) |

| G. Enzyme diluent: | 20mM K-phosphate buffer, pH 7.5 |

Procedure

| Concentration in assay mixture | |

|---|---|

| HEPES buffer | 95.2 mM |

| Glycerol | 4.76 mM |

| ATP | 3.81 mM |

| MgCl₂ |

1.90 mM |

| 4-AA | 0.469 mM |

| Phenol | 2.02 mM |

| Peroxidase | ca.5.2 U/ml |

| G-3-POD | ca.7.6 U/ml |

1. Prepare the following working solution in a brownish bottle and store on ice.

10 ml 4-AA solution (B)

20 ml Phenol solution (C)

20 ml Peroxidase solution (D)

40 ml G-3-POD solution (E)

10 ml Buffer solution (F)

2. Pipette 3.0 ml of working solution in a cuvette (d=1.0cm).

3. Add 0.1ml of enzyme solution*, mix by gently inversion and equilibrate at 37°C for about 5 minutes.

4. Add 0.05ml of glycerol solution (A) and mix by gentle inversion.

5. Record the optical density at 500nm against water for 3 to 4 minutes in a spectrophotometer thermostated

at 37°C, and calculate ΔOD per minute from the initial portion of the curve (ΔOD test).

At the same time, measure the blank rate (ΔOD blank) by the same method as test except the enzyme

diluent is added instead of the enzyme solution.

* Dissolve the enzyme preparation in ice-cold enzyme diluent (G) and dilute to 0.2-0.4U/ml with the same buffer, immediately before assay.

Calculation

Activity can be calculated by using the following formula :

ΔOD/min (OD test−OD blank ) ×Vt × df

Volume activity (U/ml) = =ΔOD/min ×4.74×df

13.3×1/2×1.0×Vs

Weight activity (U/mg)=(U/ml)×1/C

- Vt

- : Total volume (3.15ml)

- Vs

- : Sample volume (0.1ml)

- 13.3

- : Millimolar extinction coefficient of quinoneimine dye under the assay condition (㎠/micromole)

- 1/2

- : Factor based o the fact that one mole of H₂O₂ produces half a mole of quinoneimine dye

- 1.0

- : Light path length (cm)

- df

- : Dilution factor

- C

- : Enzyme concentration in dissolution (c mg/ml)

REFERENCES

- H.-S.Huang, T.Yoshida, Y.Meng, T.Kabashima, K.Ito, Y.Nishiya, Y.Kawamura, and T.Yoshimoto; J.Ferment.Bioeng., 83, 328 (1997).

| Substrate (4.5mM) | Relative activity(%) | Substrate (4.5mM) | Relative activity(%) |

|---|---|---|---|

| Glycerol | 100 | 2,3-Butanediol | 0.2 |

| Glycerol-α-monochlorohydrin | 0.1 | D-Mannitol | ― |

| Ethylene glycol | ― | D-Sorbitol | ― |

| 1,2-Propanediol | ― | D-Glucose | ― |

| 1,3-Propanediol | 0.2 | Ribitol | ― |

| 1,3-Butanediol | ― | Methanol | ― |

| 1,4-Butanediol | 0.1 | Ethanol | ― |

| Chemical | Concn.(mM) | Residual activity(%) |

Chemical | Concn.(mM) | Residual activity(%) |

|---|---|---|---|---|---|

| None | − | 100 | MIA | 1.0 | 101 |

| Metal salt | 1.0 | NaF | 1.0 | 100 | |

| MgCl₂ | 100 |

NaN₃ | 1.0 | 106 | |

| CaCl₂ |

102 | EDTA | 5.0 | 100 |

|

| Ba(OAc)₂ | 101 |

o-Phenanthroline | 1.0 | 102 | |

| FeSO₄ | 98 | α,α′-Dipyridyl | 1.0 | 101 | |

| FeCl₃ | 89 | Borate | 50 | 103 | |

| CoCl₂ | 104 | IAA | 1.0 | 99 | |

| MnCl₂ | 99 | NEM | 1.0 | 100 |

|

| ZnCl₂ | 103 | Hydroxylamine | 1.0 | 99 | |

| Cd(OAc)₂ | 101 | Triton X-100 | 1.0% | 103 | |

| NiCl₂ | 98 | Brij 35 | 0.1% | 104 | |

| CuSO₄ | 99 | Tween 20 | 0.1% | 103 | |

| Pb(OAc)₂ | 100 | Span 20 | 0.1% | 102 | |

| AgNO₃ | 10 | Na-cholate | 0.5% | 105 | |

| HgCl₂ | 2 | SDS | 0.5% | 1 | |

| Dithiothreitol |

1.0 | 100 | DAC | 0.5% | 84 |

| PCMB | 1.0 | 0 |

Ac, CH₃CO; PCMB, p-Chloromercuribenzoate; MIA, Monoiodoacetate; EDTA, Ethylenediaminetetraacetate; IAA, Iodoacetamide; NEM, N-Ethylmaleimide; SDS, Sodium dodecyl sulfate; DAC, Dimethyl-benzyl-alkyl-ammonium chloride.

To get a quote, contact us at info@toyobousa.com, or INQUIRY.